How to connect LED strip lights after you cut them? This is a common question for many customers when using LED strip lighting. After cutting LED strips, you can reconnect them in several different ways. Here are some common ways to connect LED strips, including using quick connectors, soldering, and using special connectors.

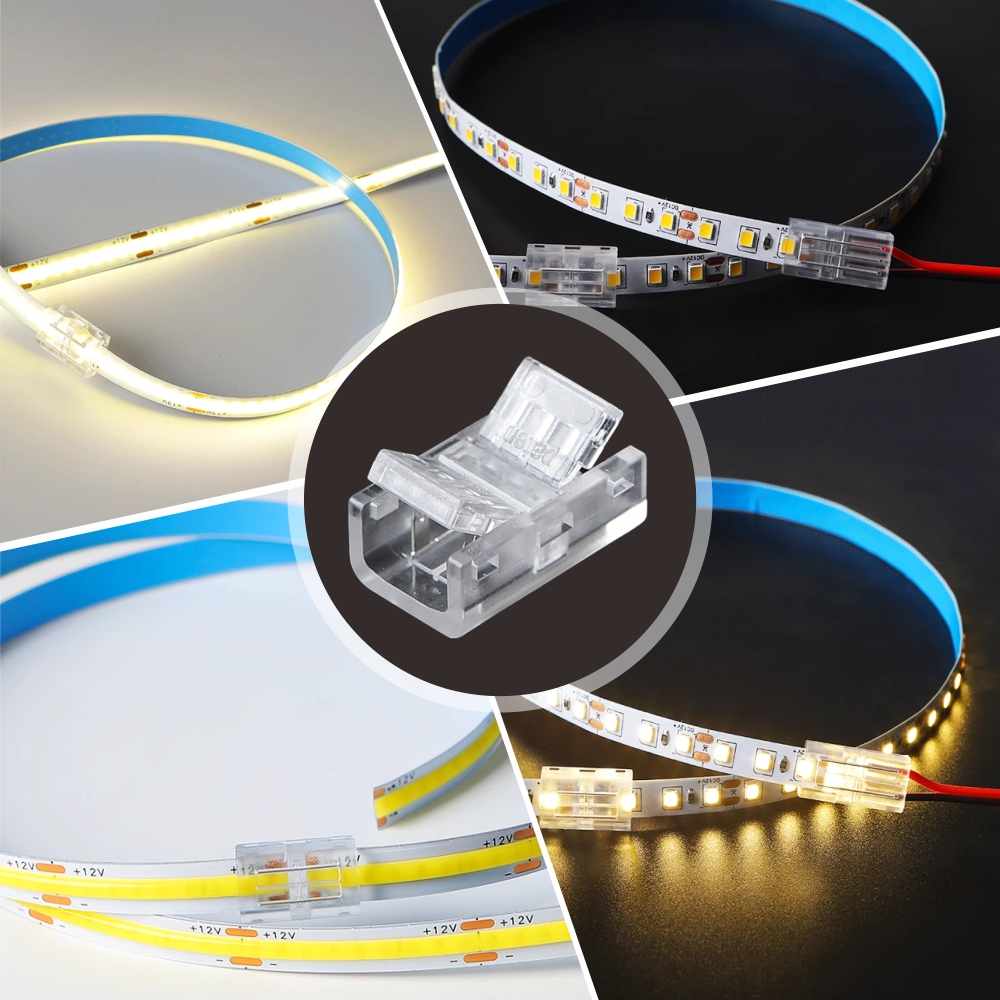

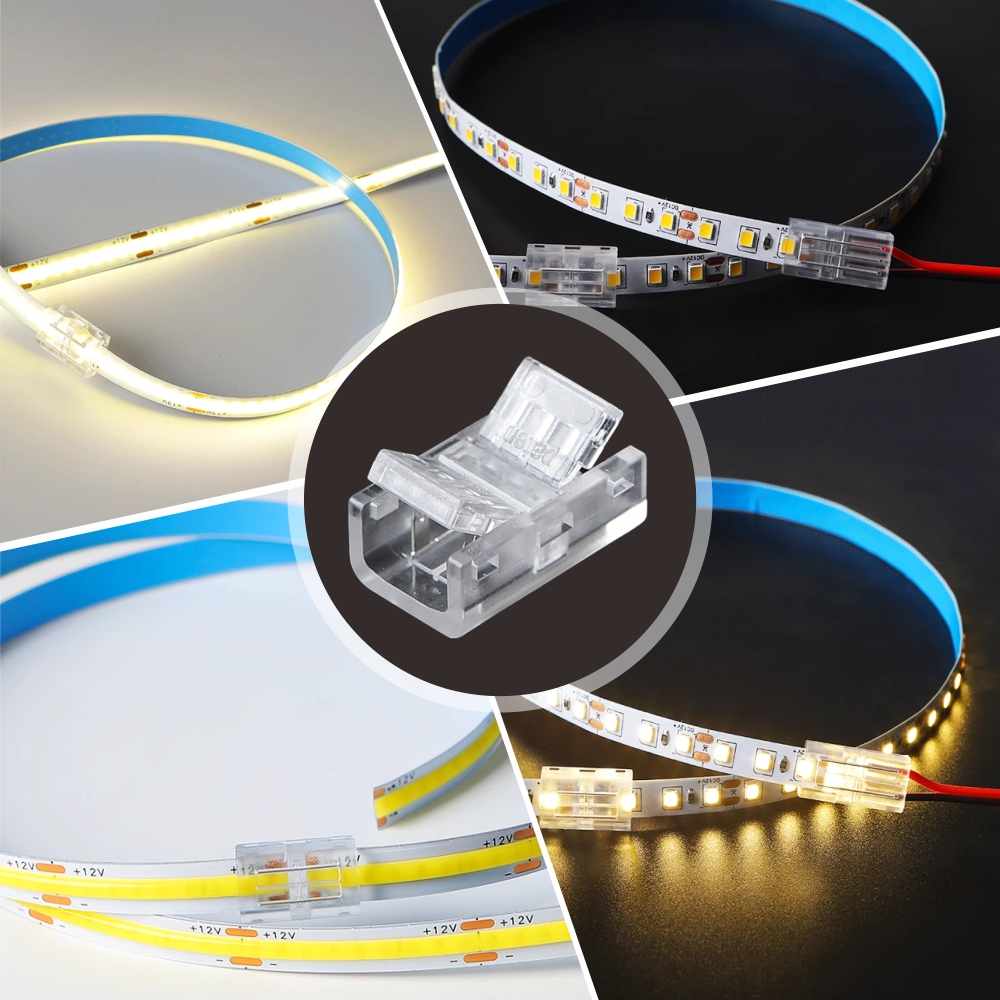

1. Using quick connector LED strips

Materials

•LED strips

•Quick connectors (usually provided with the strip or purchased separately)

•Scissors or cutting tools

•Insulating tape

Steps

1. Determine the cutting position: Find the cutting point on the strip (usually there is a cutting point every 3 LEDs) and cut at the cutting point with scissors or cutting tools.

2. Prepare the connector: Insert one end of the quick connector into the pin of the power cord or another section of strip.

3. Insert the strip: Insert the pin of the cut strip into the other end of the quick connector. Make sure the positive and negative poles are aligned correctly.

4. Check the connection: Gently pull the connector to ensure that the connection is secure.

5. Insulation treatment: Wrap the connection with insulating tape to prevent short circuits.

2. Soldering to connect LED strips

Materials

•LED strips

•Soldering iron

•Solder

•Scissors or cutting tools

•Insulating tape

Steps

1. Determine the cutting position: Find the cutting point on the strip and cut at the cutting point with scissors or cutting tools.

2. Wire stripping: Use wire strippers to strip the insulation layer of the strip pins and power cords, exposing about 5-10 mm of wire.

3. Preheat the soldering iron: Heat the soldering iron to the appropriate temperature.

4. Soldering:

•Apply solder to the soldering iron.

•Heat the pins of the strip with the soldering iron, then melt the solder and fix it on the pins.

•Solder the power cord to the corresponding pins. Make sure the positive and negative poles are correctly aligned.

5. Cooling: Let the soldering point cool naturally.

6. Insulation treatment: Wrap the soldering point with insulating tape to prevent short circuit.

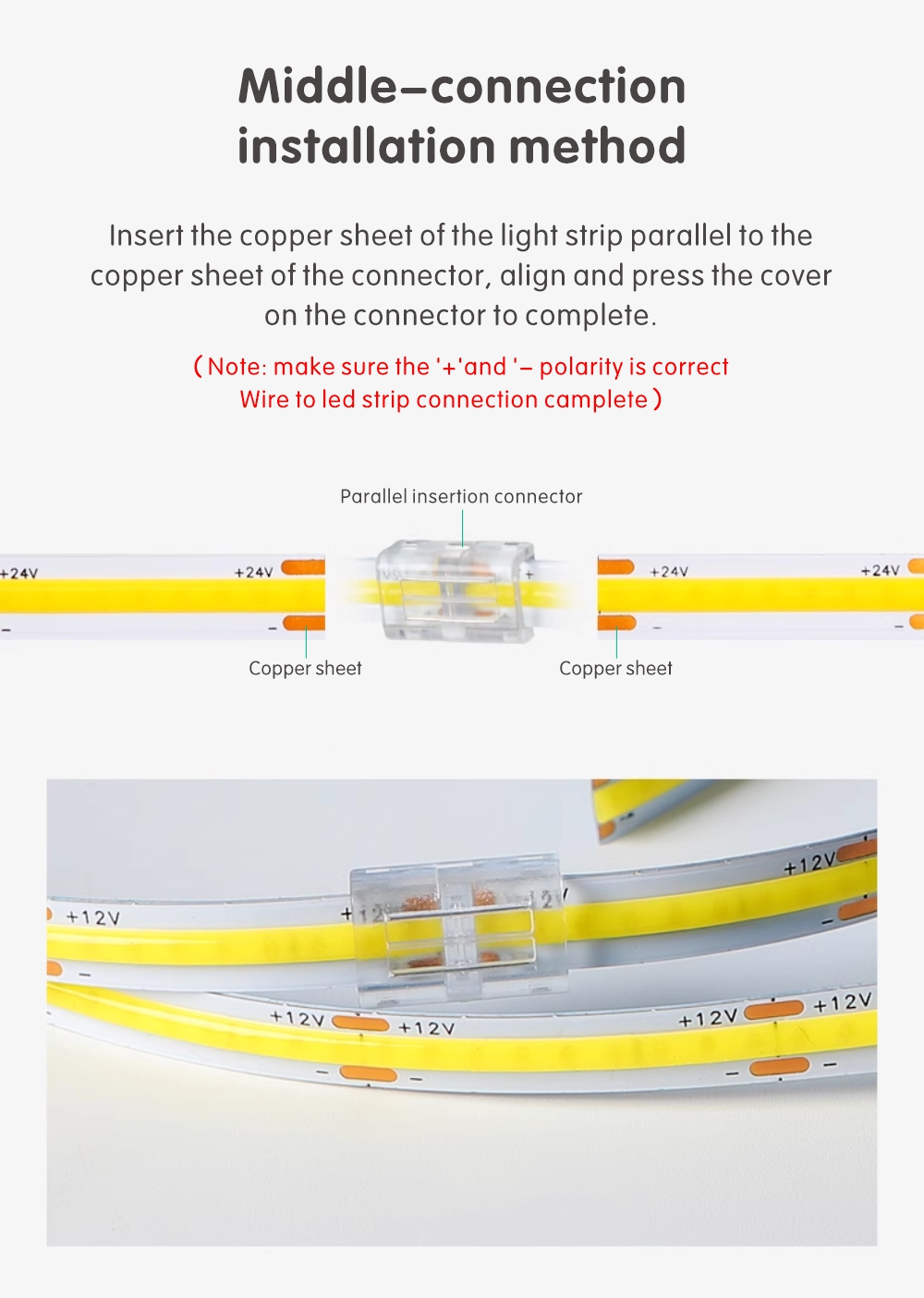

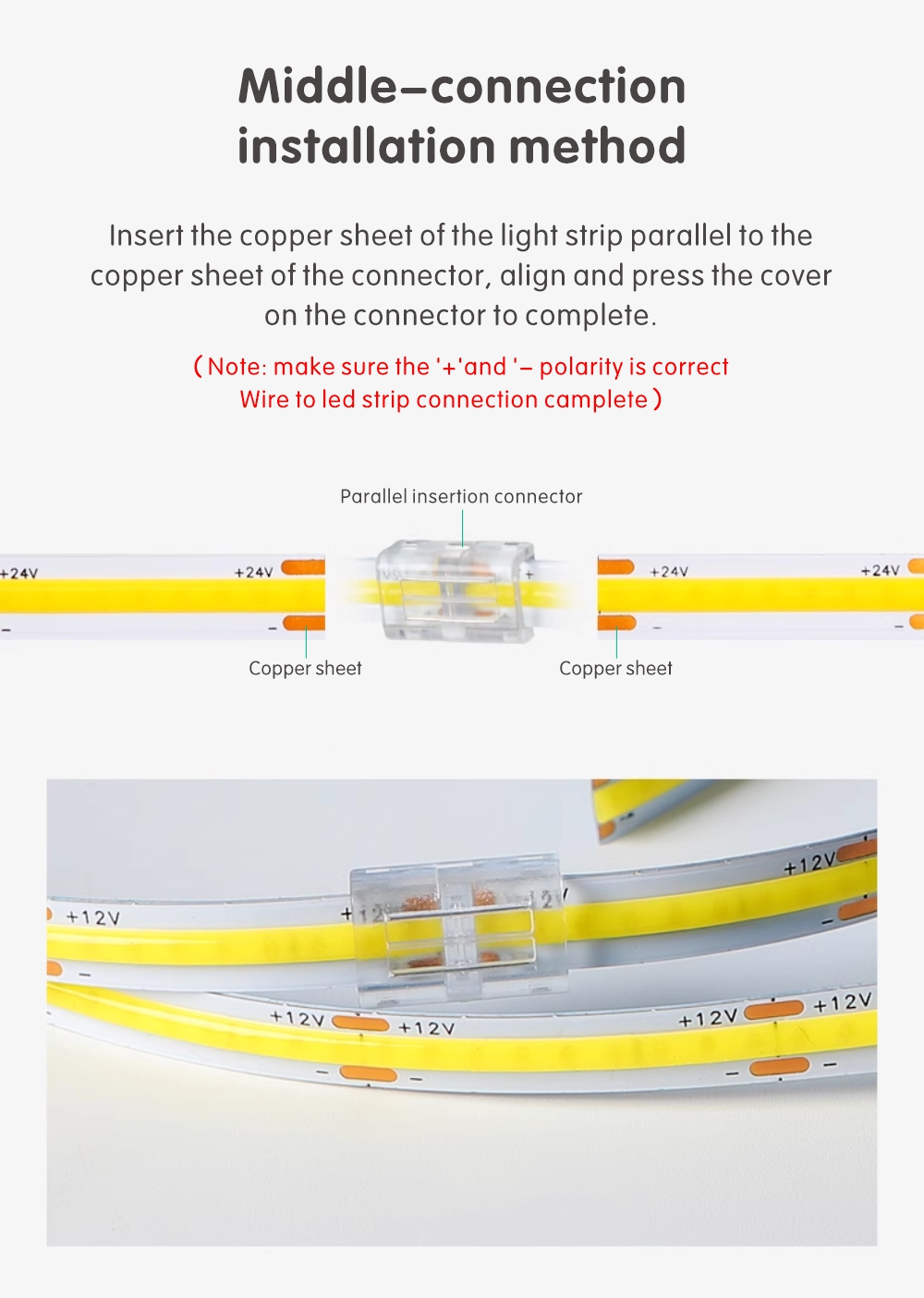

3. Use a dedicated connector LED light strip

Materials

•LED light strip

•Dedicated connector (such as plug connector, clip connector, etc.)

•Scissors or cutting tool

•Insulating tape

Steps

1. Determine the cutting position: Find the cutting point on the light strip and cut it at the cutting point with scissors or cutting tool.

2. Prepare the connector: Prepare the required connector according to the connector type. For example, the plug connector requires the light strip pin to be inserted into the plug.

3. Insert the light strip: Insert the pin of the cut light strip into the connector. Make sure the positive and negative poles are aligned correctly.

4. Fix the connector: Depending on the connector type, you may need to use screws or other fixings to fix the connector.

5. Check the connection: Gently pull the connector to ensure that the connection is firm.

6. Insulation treatment: Use insulating tape to wrap the connection to prevent short circuit.

4. Precautions

•Power matching: Make sure the voltage and current of the power adapter match the requirements of the LED light strip. Excessive voltage may damage the light strip, and insufficient current will result in insufficient brightness.

• Waterproofing: If the strip is installed in a humid environment, make sure all connections are waterproof, either by using waterproof connectors or waterproof tape.

• Safe operation: During the connection process, make sure the power is off to avoid the risk of electric shock.

• Testing: After completing the connection, test it in a small area to confirm that the strip is working properly before fully installing it.

5. Specific example Let's say you have an RGB LED strip that needs to be cut and reconnected at a certain cut point:

1. Determine the cut location: Find a cut point (usually one cut point every 3 LEDs).

2. Cut the strip: Use scissors to cut the strip at the cut point.

3. Choose the connection method: Let's say you choose to use a quick connector.

4. Prepare the connector: Insert one end of the quick connector into the pins on the power cord or another section of strip.

5. Insert the strip: Insert the pins of the cut strip into the other end of the quick connector. Make sure the red, green, blue and common positive/negative pins are correctly aligned.

6. Check the connection: Gently pull on the connector to make sure the connection is secure.

7. Insulation treatment: Use insulating tape to wrap the connection to prevent short circuit.

With the above steps, you can successfully connect the cut LED light strip. If you are not familiar with electrical operations, it is recommended to ask a professional electrician or technician to install it to ensure safety and correctness.

Best LED light strip manufacturer supplier

Maybe you are looking for the best LED light strip manufacturer supplier for your home, business, hotel, entertainment venues, etc. Or, you are just replacing an outdated LED light strip. Whether it is a shopping mall, commercial store, bar, bedroom and cabinet lighting decoration, Aglare LightingLED light strip can provide solutions to meet different needs.

Aglare Lighting is a professional LED light strip manufacturer, providing 12V 24V led light strip, rgb led light strip, waterproof outdoor led light strip, dimmable led light strip, linear led light. cob led light strip 3000K 4000K 6000K linear dimmable.